The Various Cracking Patterns for Pavement

Block Cracking

Block cracking can be recognized in asphalt pavement by cracks in squares or circles. This issue often manifests between two and three years after the asphalt surface has been laid down, and it indicates that the pavement installer used a mix that was too dry at the time the asphalt surface was laid down. Because block cracking does not extend into the sublayers, thin overlays or surface treatments can seal the cracks, restoring the integrity of the asphalt and assisting in the prevention of further cracking.

Cracking at the edges

Cracks that develop around the exterior borders of the pavement are referred to as edge cracks. Typically, they are lengthy and are laid out in the direction of the road. These fissures result from the soil beneath the road drying out and contracting, inadequate drainage, dense vegetation along the outside border of the road, and excessive vehicle usage. Cracks at the edge of the pavement can be filled with either asphalt emulsion or asphalt crack seal, depending on your preference. When repairing edge cracks, it is essential to improve the drainage surrounding the asphalt and remove plants from the edges of the paved surface.

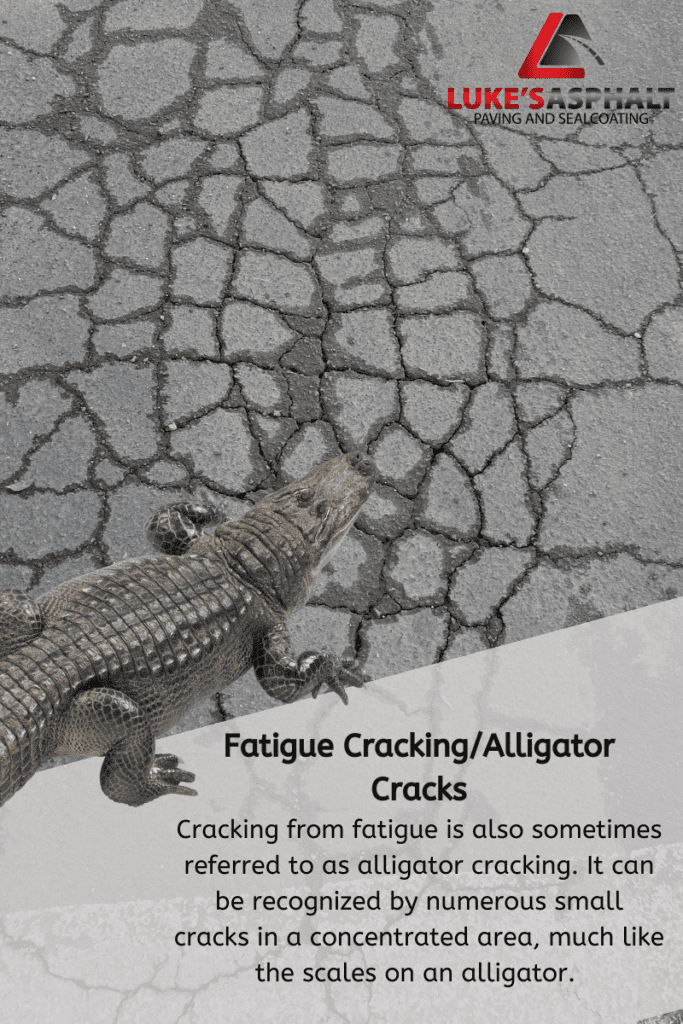

Fatigue Cracking

Cracking from fatigue is also sometimes referred to as alligator cracking. It can be recognized by numerous small cracks in a concentrated area, much like the scales on an alligator. This particular type of cracking is indicative of a defect in the design or installation of the asphalt surface, chronic high loads, or poor drainage mixed with significant alterations in temperature.

We advocate full-depth repairs since this kind of cracking signals a fundamental issue with every layer of the asphalt, from the surface to the stabilizing sub-layers. This will strengthen and restore the surface’s integrity and prevent further cracking.

Cracking in Both the Linear and Transverse Planes

Cracking that runs along the joints of the pavement is called linear cracking, also known as longitudinal cracking. Asphalt is often laid down in sections or strips when applied to extensive surfaces. Cracks can appear in the material if the joints connecting the two parts need to be formed correctly. Other contributing factors include the asphalt surface contracting, considerable daily temperature swings mixed with excess water in and around the surface, and cracks in one or more of the sublayers.

Drainage should be enhanced around the surface so that water does not penetrate the asphalt and the layers beneath it. It is recommended that the cracks be filled with an asphalt and sand mixture or an emulsion slurry combination.

Reflection Cracking

Cracking along the pavement surface that is a reflection of breaking in the sub-layers, shifting in the sub-layer joints, or shifting in the sub-layers is known as reflection cracking. These fractures are linear and often create a grid pattern over the surface of the pavement where they are found.

We advise filling these Cracks using asphalt fill mixtures and sealants to prevent moisture from penetrating the surface and causing further damage. This will also prevent the cracks from becoming worse.

Cracks Caused by Slippage.

The appearance of slippage cracks is like that of asphalt sliding across the pavement’s surface. They are recognizable by the creases and deep open spaces that they possess. This kind of cracking happens when the top layer does not adhere adequately to the layer underneath it or when there is excessive sand in the asphalt mix. Both of these factors can lead to cracking.

Cracks caused by slippage require patches of either full or partial depth, depending on the severity of the damage and the degree of slippage along the surface. Patches can be complete or partial depth.

Would you like any help with any of the issues mentioned above? Request a complimentary evaluation right away!

Call Luke's Asphalt Today At 830-438-4030